Indirect application of liquid nitrogen cooling

Editor:adminClick:

Time:2018-06-09 09:29

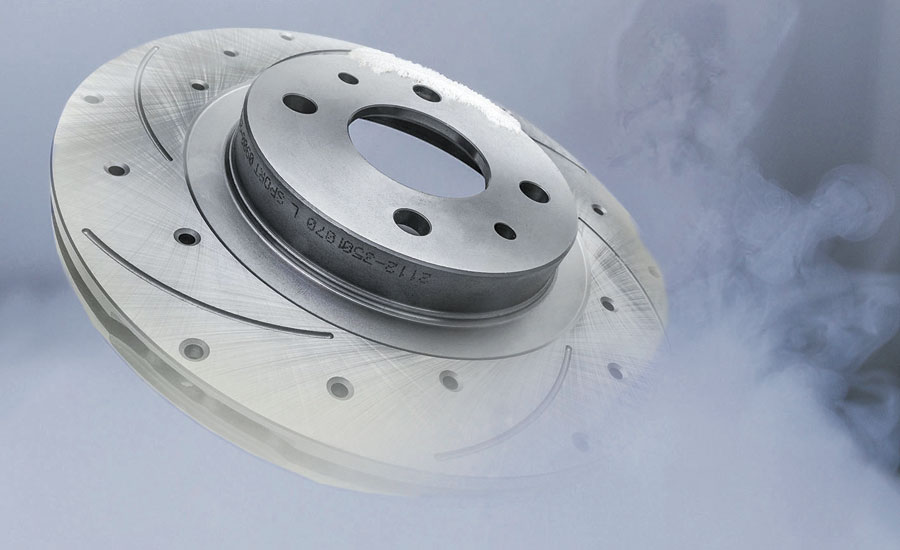

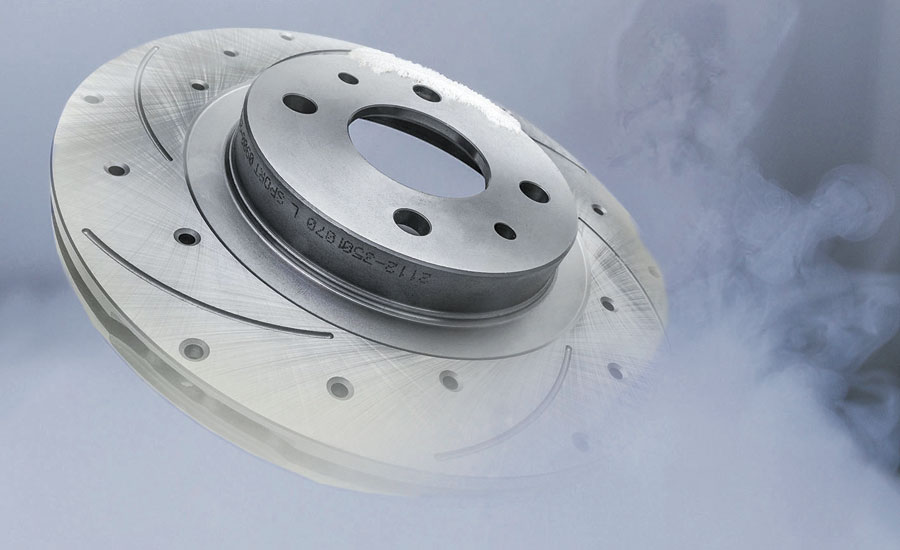

We use low-temperature brittleness of some steel materials to carry out cryogenic cutting and grinding of liquid nitrogen, which can improve the cutting processability and improve the processing quality. The direct application of liquid nitrogen as a cutting fluid can significantly reduce the cutting temperature, improve the machining accuracy and surface quality, and prolong the service life of the tool (grinding wheel). Liquid nitrogen is a more effective and economic alternative to cutting fluids in future cutting and grinding processes. .

The indirect use of liquid nitrogen cooling is mainly the tool cooling method, that is, the tool is continuously cooled during processing, so that the cutting heat is rapidly taken away from the tool, particularly at the tool tip, and the tool tip is always maintained at a low temperature. Researchers at Lincoln University in the United States used a CBN (PCBN) tool equipped with a new cooling system produced by Sandvik Corporation to carry out experimental research. The tool stores liquid nitrogen in a square box on the upper part of the turning tool and is imported from the inlet. Outflow.

Tests have shown that when liquid nitrogen cools, the turning tool life is extended by 10 times, wear is reduced by 1/4, and a smaller surface roughness can be obtained.

There is also a special indirect method of jet cooling. Some Japanese scholars have developed a jet cooling system. The cooling gas used in the system is cooled by liquid nitrogen in a heat exchanger, and its temperature is lower than -50°C. The cooling gas is directly injected at the grinding point. It was found that the residual compressive stress of the workpiece material after grinding is larger than that of the grinding fluid, and the distribution area of the residual compressive stress is also widened. Residual compressive stress can increase the fatigue life of parts, and is very important for some parts, such as aircraft parts. The use of a solid lubricant treated CBN grinding wheel, or the addition of a very small amount (10 l/h) of super-sperm vegetable oil during processing, can play a better lubrication effect in processing.

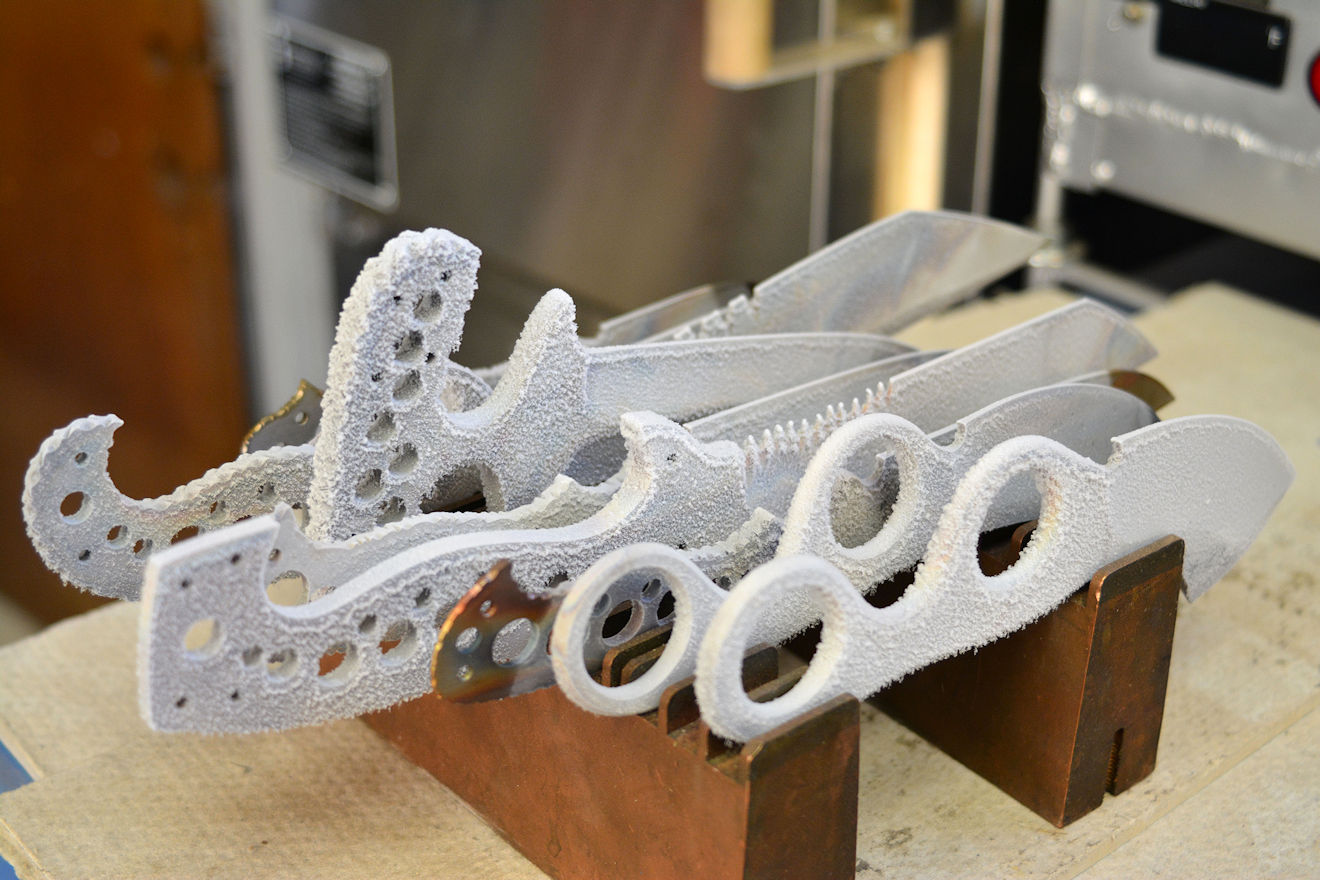

The use of liquid nitrogen cooling at low temperature (ultra-low temperature) processing solves the difficult processing problems of some difficult-to-process metal materials, non-metal materials and composite materials. When using liquid nitrogen cooling and cutting grinding, some lubricants need to be used to solve the problem of poor lubricity in the chip formation process; at the same time, the newly generated metal surface on the workpiece has a strong chemical activity and will quickly rust when exposed to air. Therefore, some rust inhibitors need to be used to prevent the workpiece and the machine from rusting.

Keywords:liquid nitrogen cooling,

liquid nitrogen freezing,

liquid nitrogen containers,

liquid nitrogen storage

Relevant Information

- 10L Liquid Nitrogen Containers/Tanks/Dewars

- YDS series Liquid Nitrogen Tank

- 10 key pints of liquid nitrogen containers that you should know

- Application of liquid nitrogen freezing in dermatology clinic

- Principle and Technology of Liquid Nitrogen Freezing

- Biological Cryogenic Liquid Nitrogen Containers For Storage

- Biological Cryogenic Liquid Nitrogen Containers For Storage

Latest Products

- 16L Ice Cream Liquid Nitrogen Co

6L Ice Cream Liquid Nitrogen Container Liquid Nitrogen Tank W...[more]

- 210L YDS-10 Small Capacity Liqui

10L YDS-10 Small Capacity Liquid Nitrogen Storage Container f...[more]

- 310L Liquid Nitrogen Containers/

10L Liquid Nitrogen Containers/Tanks/Dewars We offer a wide r...[more]

- 410l Biological Cryogenic Liquid

10l Biological Cryogenic Liquid Nitrogen Container We offer a...[more]

- 5Cheap price 50caliber 10L Liqui

Cheap price 50caliber 10L Liquid Nitrogen Biological Containe...[more]

Rankings Of Similar Articles

- 10L Liquid Nitrogen Containers/Tanks/Dewars

- YDS series Liquid Nitrogen Tank

- 10 key pints of liquid nitrogen containers that you should kn

- Application of liquid nitrogen freezing in dermatology clinic

- Principle and Technology of Liquid Nitrogen Freezing

- Biological Cryogenic Liquid Nitrogen Containers For Storage

- Biological Cryogenic Liquid Nitrogen Containers For Storage

Latest Information

- Be careful when filling liquid nitrogen

- The usage of the liquid nitrogen tank

- Liquid nitrogen sprayer YDL-250 250ml for face spot treatment

- General knowledge about liquid nitrogen ice cream

- Advantages of cryopreservation of liquid nitrogen tanks

- The principle and precautions of liquid nitrogen cryotherapy

- The product structure of liquid nitrogen tank

- The maintenance tips of Liquid nitrogen stroage tank

- Liquid nitrogen tank cell storage

- The applications of liquid nitrogen in medicine and industry