Liquid nitrogen cryogenic treatment

Editor:adminClick:

Time:2018-04-11 17:41

Liquid nitrogen cryogenic treatment

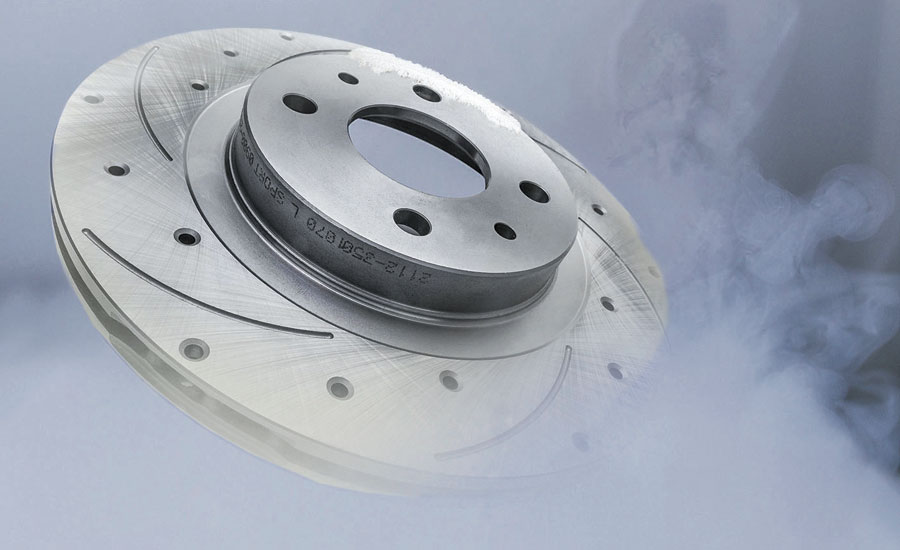

Cryogenic treatment is a method in which the material is treated with liquid nitrogen as a cooling medium. The liquid nitrogen cryogenic treatment technology was first applied to wear-resistant tools and mold cutting tool materials, and later extended to alloy steels, hard alloys, etc. The method can change the internal structure of metal materials, thereby improving the mechanical and processing properties of the materials. It is one of the latest toughening processes.

Cryogenic treatment is a method in which the material is treated with liquid nitrogen as a cooling medium. The liquid nitrogen cryogenic treatment technology was first applied to wear-resistant tools and mold cutting tool materials, and later extended to alloy steels, hard alloys, etc. The method can change the internal structure of metal materials, thereby improving the mechanical and processing properties of the materials. It is one of the latest toughening processes.

Cryogenic treatment mechanism: After cryogenic treatment, the retained austenite in the internal structure of the metal material transforms into martensite, and it can also precipitate disperse carbides in the martensite, which not only eliminates the residual stress in the martensite, but also It can strengthen the matrix of martensite and improve its hardness and wear resistance.

Cryogenic treatment equipment consists mainly of liquid nitrogen tanks, liquid nitrogen transfer systems, cryogenic tanks, and control systems. In application, liquid nitrogen cryogenic treatment is repeated several times. On the other hand, ultrafine carbides precipitate from martensite transformed from retained austenite at the time of deep cryogenic cooling, and on the other hand, fine carbides continue to precipitate in quenched martensite. The repeated process can increase the compressive strength, yield strength and impact toughness of the matrix, increase the toughness of the steel, and at the same time significantly increase the resistance to impact abrasion.

At present, the liquid nitrogen cryogenic treatment technology has gradually expanded from the application of tools and die steel to automotive and construction machinery parts and non-metal processing and other fields. However, in the promotion, the following problems have also been discovered:

1. The effect of liquid nitrogen cryogenic treatment technology on the performance of metal materials (tools, molds and tools) is very obvious. However, the cryogenic treatment process is very strict on the equipment and the control accuracy, and the main factors affecting the effect are the deep-cooled box structure, liquid nitrogen refrigeration method, temperature control accuracy and uniformity.

2. The research on the mechanism of cold treatment is less and less comprehensive. Most of the R&D focuses on metallography and heat treatment, but less research on physics, which also limits the mastery and use in process applications.

3, In addition, the law of deformation of the workpiece caused by the cold treatment method has not yet been fully grasped, and it needs further research and exploration as the final processing of the workpiece.

Cryogenic treatment is suitable for the application of mold materials, but there is still much room for research on other materials.

Relevant Information

- How to remove samples from liquid nitrogen container

- 10 L Liquid Nitrogen Tank LN2 Dewar Cryogenic Container 6 Canisters

- Liquid nitrogen container 20 Liter portable cryogenic cylinder semen storage ta

- Liquid nitrogen container 20 Liter portable cryogenic cylinder semen storage ta

- Liquid nitrogen container 20 Liter portable cryogenic cylinder semen storage ta

- Transport Cryogenic Storage Liquid Nitrogen Biological Container

- Portable Storage Series LN2 Container

- LAB YDS-10 Liquid Nitrogen Biological Container Cryogenic Tank Supplier

- Liquid nitrogen tanks have storage type and transportation type.

- Safe handling of liquid nitrogen, liquid nitrogen containers

Latest Products

- 110m3 double wall cryogenic Liqu

Cryogenic Liquid Tanks are available in vertical or horizonta...[more]

- 2vertical stainless steel pressu

Cryogenic Liquid Tanks are available in vertical or horizonta...[more]

- 310 cubic meters cryogenic Liqui

Cryogenic Liquid Tanks are available in vertical or horizonta...[more]

- 4GB150 pressure vessels cryogeni

Cryogenic Liquid Tanks are available in vertical or horizonta...[more]

- 5New double Vertical cryogenic L

Cryogenic Liquid Tanks are available in vertical or horizonta...[more]

Rankings Of Similar Articles

- How to remove samples from liquid nitrogen container

- 10 L Liquid Nitrogen Tank LN2 Dewar Cryogenic Container 6

- Liquid nitrogen container 20 Liter portable cryogenic cylinde

- Liquid nitrogen container 20 Liter portable cryogenic cylinde

- Liquid nitrogen container 20 Liter portable cryogenic cylinde

- Transport Cryogenic Storage Liquid Nitrogen Biological Contai

- Portable Storage Series LN2 Container

- LAB YDS-10 Liquid Nitrogen Biological Container Cryogenic Tan

- Liquid nitrogen tanks have storage type and transportation ty

- Safe handling of liquid nitrogen, liquid nitrogen containers

Latest Information

- How long is the liquid nitrogen stored in the liquid nitrogen

- When liquid nitrogen is full, the neck of liquid nitrogen tan

- How to reduce liquid nitrogen evaporation

- How to Keep Aircraft Aluminum Liquid Nitrogen Tank

- What are the factors affecting semen quality in liquid nitrog

- How to Clean and Maintain Liquid Nitrogen Tank after Freezing

- What causes the liquid nitrogen tank to be abandoned?

- Cell Processing Method for Dropping into Liquid Nitrogen Tank

- Liquid Nitrogen Tank and Frozen Semen Container

- Packaging requirements for transporting goods in liquid nitro